Preventive maintenance depends on organization. Technicians need to spot wear, identify faults, and perform quick fixes before problems escalate.

Nylon cable ties make that possible.

They secure, separate, and protect components in electrical, mechanical, and industrial systems — reducing downtime, simplifying inspections, and keeping operations safe. More than fasteners, nylon cable ties are a quiet backbone of every preventive maintenance program.

The Value of Preventive Maintenance

Every maintenance professional knows: it’s cheaper to prevent failure than to repair it. Regular inspections, cleaning, and cable management keep equipment reliable and compliant.

But messy wiring, loose hoses, or unanchored components can hide damage or create new risks. Nylon cable ties provide the control needed to maintain clarity and accessibility across complex systems.

Why Nylon Cable Ties Dominate Maintenance Work

Nylon ties, especially those made from

Nylon 6/6, remain the preferred choice because of their unique balance of

strength, flexibility, and chemical resistance.

They can withstand years of vibration, temperature changes, and handling without cracking or loosening. For technicians, they’re fast, clean, and easy to replace during service intervals.

Core Advantages

-

Durability: Resists fatigue and stress cracking in both hot and cold conditions.

-

Chemical Resistance: Handles oils, fuels, lubricants, and cleaning solvents.

-

Temperature Range: From -40°F to +185°F for standard nylon; up to +250°F for heat-stabilized variants.

-

Non-Conductive: Ensures electrical safety in panels and enclosures.

-

Variety: Available in releasable, marker, or weather-resistant types for specific maintenance needs.

1. Securing Cables and Preventing Failure

Loose cables can cause vibration wear, electrical arcing, or even fire hazards. Nylon cable ties fix wiring firmly in place, preventing damage from constant motion or thermal cycling.

In rotating machinery or conveyor systems, ties reduce friction points and keep wires clear of moving parts. When used with

mounting bases or

adhesive pads, they protect wiring in hard-to-reach areas where vibration is strongest.

Even in HVAC or power distribution systems, properly spaced nylon ties improve airflow and prevent heat buildup — extending the life of both insulation and equipment.

Learn more: Here's How to Distinguish the Quality of Nylon Cable Ties.

2. Improving Visual Inspections

Preventive maintenance relies heavily on

visual clarity. Bundled, labeled cables make inspections faster and safer.

When wiring is secured with uniform spacing and consistent tie placement, issues like discoloration, abrasion, or corrosion stand out immediately. This organization also ensures maintenance logs remain accurate — technicians can trace circuits and components without confusion.

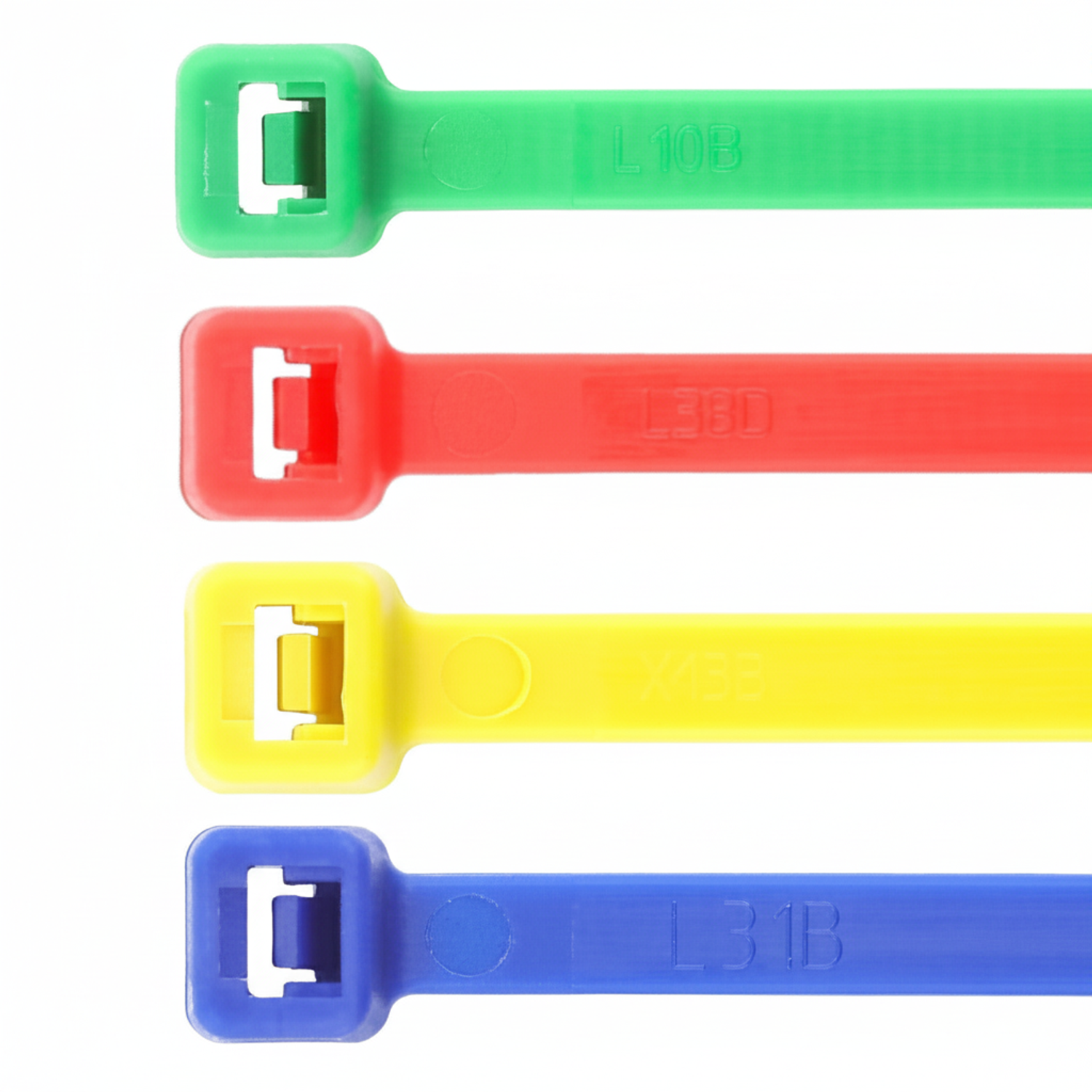

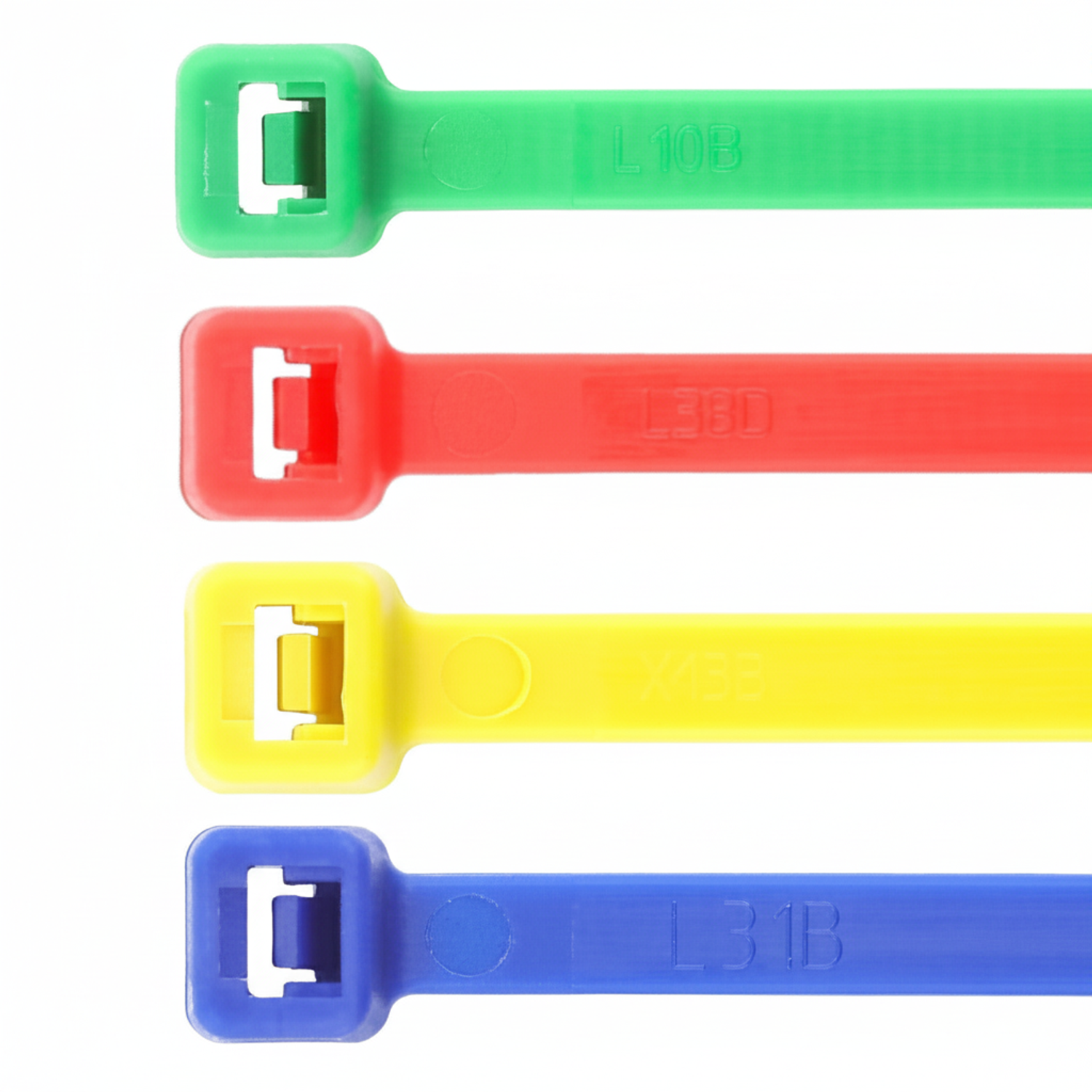

For even greater efficiency,

colored nylon ties can mark inspection intervals, system phases, or risk categories. For instance, red might indicate power, blue for communication, and green for grounding lines.

3. Reducing Mechanical Stress

Cables, hoses, and pneumatic lines under constant tension degrade faster. Nylon cable ties distribute pressure evenly across bundles, reducing stress concentrations.

They also prevent “whip” in high-vibration areas — a common cause of fatigue failures in flexible conduits and cables. By isolating motion, ties protect both the wiring and the connectors that link them to critical systems.

Releasable nylon ties are especially useful in preventive maintenance because they allow periodic adjustments without cutting or replacing fasteners.

4. Maintaining Cleanliness and Safety

Cluttered wiring isn’t just inefficient — it’s unsafe. Poorly managed cables collect dust, restrict airflow, and block access to service points. Nylon ties eliminate clutter, making work areas cleaner and reducing trip hazards.

In industrial settings,

flame-retardant nylon cable ties reduce ignition risks, while

low-smoke halogen-free variants minimize toxic emissions in sensitive facilities. Keeping cables secured also prevents accidental disconnection of safety sensors or emergency systems.

5. Extending Component Lifespan

Every secured cable is one less source of friction, wear, or overheating. By stabilizing cables and preventing contact with sharp edges or vibrating surfaces, nylon ties directly extend component service life.

Over time, this simple improvement leads to fewer replacements, less downtime, and lower maintenance costs.

In harsh conditions,

UV-stabilized or weather-resistant nylon ensures outdoor installations stay intact even under constant sun, moisture, or frost.

6. Supporting Predictive Maintenance Technologies

Many modern PM programs include

sensors and data-logging equipment for vibration, heat, or current monitoring.

Nylon cable ties help secure these sensors in precise positions — ensuring consistent data collection. Because nylon is non-conductive and vibration-resistant, it doesn’t interfere with measurements, making it ideal for holding thermocouples, accelerometers, or fiber-optic lines.

By keeping these systems stable, nylon ties indirectly enhance the accuracy of predictive maintenance analytics.

7. Simplifying Maintenance Workflows

Speed is critical in preventive maintenance, especially when multiple systems must be serviced on tight schedules. Nylon cable ties allow for fast, tool-free installation and easy identification of previous work.

Releasable or marker ties save technicians from re-bundling entire harnesses. A well-organized cable layout also helps standardize inspection checklists — each tie becomes part of a repeatable system that technicians across shifts can follow.

This consistency is essential in large facilities where preventive maintenance depends on shared records and visual uniformity.

8. Reducing Costs and Downtime

Downtime is the enemy of efficiency. When cables are well-managed, failures are easier to predict, and small issues are faster to repair.

Using durable nylon ties reduces both the frequency and cost of emergency repairs by preventing common wear points. Compared to metallic fasteners, they’re inexpensive, lighter, and corrosion-resistant — offering long-term savings without compromising safety.

The result: fewer service interruptions, lower replacement costs, and improved return on maintenance investment.

9. Choosing the Right Nylon Tie for Preventive Maintenance

Not all nylon cable ties are created equal. Matching the tie to the environment and application ensures optimal performance.

| Application |

Recommended Nylon Tie Type |

Key Feature |

| Electrical maintenance |

UL-rated, flame-retardant |

Safe around live circuits |

| Outdoor systems |

UV-stabilized nylon |

Resists sunlight and weather |

| High-temperature zones |

Heat-stabilized nylon |

Withstands up to +250°F |

| Repetitive servicing |

Releasable nylon |

Reusable, easy to adjust |

| Corrosive environments |

Weather-resistant nylon |

Improved chemical resistance |

| Identification |

Marker or colored ties |

Quick circuit recognition |

Whenever possible, use ties compliant with

UL 62275 or equivalent standards to ensure material quality and load integrity.

10. Best Practices for Installation

Even the best cable tie won’t perform if it’s installed incorrectly. Proper application is essential in preventive maintenance environments.

a) Avoid Over-Tightening

Too much tension can pinch insulation or deform soft hoses. Use a

tensioning tool to apply consistent, manufacturer-recommended pressure.

b) Keep Bundles Even

Group cables of similar size and function together. Avoid mixing power and signal lines in the same bundle to prevent interference.

c) Leave Service Loops

Always leave enough slack for future servicing or replacement. Overtight layouts make inspections difficult.

d) Replace Aged Ties

Over time, nylon can degrade from heat or UV exposure. During scheduled inspections, replace any ties showing brittleness or discoloration.

e) Clean Before Applying Adhesive Mounts

If using adhesive bases, clean the surface to ensure the pad bonds firmly. Contamination reduces adhesion strength.

By following these steps, maintenance teams ensure reliable fastening that lasts through multiple inspection cycles.

Integrating Nylon Ties Into a Maintenance Strategy

A well-structured preventive maintenance plan includes not only inspections and lubrication but also

cable integrity checks. Nylon cable ties are part of that equation — both as a maintenance tool and a condition indicator.

For instance, cracked or brittle ties can signal excessive heat or chemical exposure nearby. Replacing them proactively prevents secondary failures in cables or connectors.

By tracking cable tie condition over time, technicians can even identify patterns of environmental stress that inform broader system improvements.

Wrapping Up

Nylon cable ties may be small, but their impact on preventive maintenance is significant. They keep systems organized, stable, and safe — allowing technicians to focus on preventing problems instead of reacting to them.

Strong, flexible, and resistant to the toughest industrial environments, nylon cable ties are one of the most effective tools in any maintenance professional’s arsenal.

For more insights and tips on

cable ties and other related products, explore

cabletiesunlimited.com, get a

quick and free quote, and follow us on our social media communities on

Facebook and

Instagram.

Every secured cable is one less source of friction, wear, or overheating. By stabilizing cables and preventing contact with sharp edges or vibrating surfaces, nylon ties directly extend component service life.

Over time, this simple improvement leads to fewer replacements, less downtime, and lower maintenance costs.

In harsh conditions, UV-stabilized or weather-resistant nylon ensures outdoor installations stay intact even under constant sun, moisture, or frost.

Every secured cable is one less source of friction, wear, or overheating. By stabilizing cables and preventing contact with sharp edges or vibrating surfaces, nylon ties directly extend component service life.

Over time, this simple improvement leads to fewer replacements, less downtime, and lower maintenance costs.

In harsh conditions, UV-stabilized or weather-resistant nylon ensures outdoor installations stay intact even under constant sun, moisture, or frost.