Outdoor installations put cable ties to the test. They face constant sun, rain, snow, and wind. Over time, the environment breaks down weak materials. One problem that frustrates many installers is rust stains. These stains can appear on siding, vehicles, or equipment when the wrong type of tie is used outdoors.

Rust stains are not just cosmetic. They can indicate corrosion, which weakens the tie and compromises security. In critical outdoor projects like telecom towers, solar farms, or transportation infrastructure, a single failed tie can lead to larger failures. Avoiding rust requires choosing the right materials, applying correct techniques, and maintaining installations.

This guide explores why rust stains occur, how to prevent them, and which cable ties are designed for outdoor reliability.

Why Rust Stains Appear

Rust forms when metals oxidize in the presence of moisture and oxygen. Some cable ties use metal locking mechanisms. If these are not stainless steel or corrosion-resistant alloys, they can rust. As water carries particles across surfaces, it leaves stains.

Plastic ties without proper UV resistance also degrade over time. As they weaken, embedded metal parts may corrode and stain nearby surfaces. Even stainless steel ties can leave stains if contaminants collect on them, though this is less common.

Risks of Rust Outdoors

Rust stains cause more than unsightly marks. They signal deeper problems.

- Structural weakness: Corrosion weakens the locking mechanism.

- Cable damage: Rust particles can scratch or cut insulation.

- Surface damage: Stains on painted siding or vehicles can be costly to clean.

- System failure: Failed ties risk loose cables, safety hazards, and downtime.

In industries where uptime matters, such as telecommunications or energy, these risks add significant costs.

Common Causes of Rust Stains on Cable Ties

- Poor-quality materials: Low-grade metals rust quickly outdoors.

- Lack of UV stabilization: Nylon ties without UV additives degrade, exposing components.

- Harsh environments: Coastal areas with salt spray accelerate corrosion.

- Improper installation: Over-tightening damages protective coatings, leading to rust.

- Contamination: Dirt or metal particles settling on ties cause surface staining.

Materials That Resist Rust

Weather-Resistant Nylon

Weather-resistant ties include additives that protect against moisture and temperature extremes. They last longer outdoors than standard nylon but may still struggle in salt-heavy air.

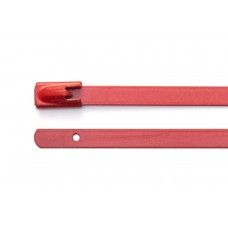

Stainless Steel Cable Ties

Stainless steel ties are the gold standard for outdoor durability. Made from grades like 304 or 316 stainless steel, they resist corrosion even in marine environments. Their smooth design also prevents staining when properly installed.

Coated Stainless Steel

Some stainless steel ties come with epoxy or PVC coatings. These prevent direct metal contact with surfaces, reducing staining risks. They also add a layer of insulation, protecting cables from abrasion.

Preventing Rust Stains

Select the Right Tie

Always match tie material to the environment. Nylon ties are fine for short-term outdoor use, but stainless steel is best for long-term projects.

Use Coated Options

If working near visible surfaces like siding or painted equipment, coated stainless steel ties prevent metal-on-surface contact, avoiding stains.

Install Carefully

Over-tightening stainless steel ties can scratch protective coatings. Use tensioning tools for consistent, safe installation.

Perform Maintenance

Regularly inspect ties in outdoor environments. Replace ties that show wear, discoloration, or surface buildup before stains form.

Clean Surrounding Surfaces

Rust can spread from outside contaminants. Keep equipment and siding clean to minimize staining.

Industry Examples

Telecommunications

Cell towers exposed to wind and rain rely on stainless steel ties. Without them, rust stains and corroded locks risk communication outages.

Solar Energy

Solar farms often use coated stainless steel ties. These prevent stains on panels and support structures while resisting UV and heat.

Automotive and Transportation

Vehicles and roadside equipment face constant moisture and salt. Stainless steel ties resist corrosion in harsh winter road conditions.

Marine Applications

Boats and coastal equipment demand 316 stainless steel ties. Their superior corrosion resistance ensures reliability near saltwater.

Tools That Help

Using the right tools ensures ties are installed correctly and stay secure.

- Stainless steel tension tools: Apply consistent tension without damaging coatings.

- Flush cutters: Provide smooth edges when cutting nylon ties, reducing weak points.

- Protective gloves: Prevent contamination of ties during installation.

Product Review: Stainless Steel Cable Ties

Cable Ties Unlimited offers Stainless Steel Cable Ties designed to resist rust and corrosion in outdoor environments. Crafted from high-grade stainless steel, they maintain tensile strength even in harsh conditions.

Available in uncoated or coated options, these ties provide flexibility for different applications. The ball-locking mechanism ensures secure fastening, while rounded edges protect cable insulation. For long-term outdoor projects, these ties deliver unmatched reliability and stain prevention.

From telecom towers to marine equipment, stainless steel cable ties are the best defense against rust stains. Their durability makes them a cost-effective solution for U.S. industries where outdoor reliability is essential.

Mistakes to Avoid

- Using indoor ties outdoors: Standard nylon ties fail quickly in sunlight and moisture.

- Mixing metals: Combining different metals in contact accelerates corrosion.

- Neglecting inspections: Ignoring maintenance leads to unexpected failures.

- Overlooking coatings: Bare steel against painted surfaces increases stain risk.

Cost Versus Value

Stainless steel ties cost more upfront, but they outlast nylon many times over. Their resistance to rust and staining prevents costly repairs, replacements, and downtime. For critical outdoor projects, their value far exceeds the initial investment.

Future of Outdoor Cable Ties

Material innovation is reducing rust risks even further. Manufacturers are developing advanced coatings that combine strength with non-marking surfaces. Sustainable options, such as recyclable weather-resistant polymers, may one day replace nylon for short-term outdoor use.

Smart monitoring solutions are also on the horizon. Ties embedded with sensors could alert technicians when corrosion begins, allowing preventive maintenance before stains and failures appear.

Wrapping Up

Rust stains from outdoor cable ties are more than an eyesore. They signal corrosion that threatens system reliability. Choosing the right materials, applying careful installation techniques, and performing maintenance ensures long-term performance.

Products like Stainless Steel Cable Ties from Cable Ties Unlimited deliver rust-free, reliable performance. Available in coated and uncoated designs, they protect both cables and surrounding surfaces.

For industries that depend on outdoor reliability, avoiding rust stains begins with the right cable ties. With stainless steel and proper installation, outdoor projects remain secure, clean, and dependable.

For more insights and tips on cable ties and other related products, explore cabletiesunlimited.com, get a quick and free quote, and follow us on our social media communities on Facebook and Instagram!